question?

If you have questions about custom magnets,please leave us a message,we will reply you as soon as we can!

Contact UsWelcome to visit Xiamen Kings Magnet Co.,Ltd. Neodymium Magnets Manufacturer

Call Us Now !

0086 0592 5663916Order Online Now !

brian@kingsmagnet.com

Xiamen Kingsmagnet has been in magnet industry for 10 more years. We could provide the highest quality black epoxy block shaped neodymium magnets.

Read More

Xiamen Kingsmagnet has been in magnet industry for 10 more years. We could provide the high quality and black epoxy ring magnet for you.

Read More

Xiamen Kingsmagnet has been in magnet industry for 10 more years. We could provide the high quality black epoxy thin block neodymium magnets for you.

Read More

Xiamen Kingsmagnet has been in magnet industry for 10 more years. We could provide the high quality black epoxy rectangular neodymium magnets for you.

Read More

Xiamen Kingsmagnet has been in magnet industry for 10 more years. We could provide the high quality double countersunk black epoxy block neodymium magnets for you.

Read More

Xiamen Kingsmagnet has been in magnet industry for 10 more years. We could provide the highest quality black shaped neodymium magnets.

Read More

Xiamen Kingsmagnet has been in magnet industry for 10 more years. We could provide the highest quality rubber disc magnet neodymium.

Read More

Xiamen Kingsmagnet has been in magnet industry for 10 more years. We could provide the highest quality and custom size cube neodymium magnets for you.

Read More

If you have questions about custom magnets,please leave us a message,we will reply you as soon as we can!

Contact UsMOQ :

1origin :

China1,KMMC(0.1-10NM) Magnetic Coupling

Model

Torgue

Inner Rotor

Outer Rotor

NM

A

B

C

D

E

F

G

H

I

KMMC-0.1

0.1

12.7

4

7

15

6

17.5

26

19

27

KMMC-0.2

0.2

18

6

8

20

8

23

35

28

44

KMMC-0.3

0.3

22

8

8

16

8

28

44

22

36

KMMC-1

1

28

10

12

20

10

25

52

28

44

KMMC-3

3

35

12

16

25

12

43

58

35

55

KMMC-10

10

58

16

20

35

29

66

88

50

80

2,KMMC(3-80NM) Magnetic Coupling

Remarks

1. Air gap between inner rotor and outer rotor can be designed according to customer's requirements,

2. Working temperature: NdFeB≤140℃,Sm2C017≤280℃;

3. The inertia balance for inner and outer rotor is G6. 3:

4. Material:

Inner rotor: stainless steel 316316L

Outer rotor: carbon steel/Zn coated

Sealing can: stainless steel 316/316L

Flange:carbon steel /Zn coated

5. Pressure bearing of sealing can: 1-2Mpa

6. All the dimensions are in millimeter

Magnetic Grate-Round shape series

Magnetic Grate-Round shape series

Welded series:Max magnetic strength 11000GS Screw fix series:Max magnetic strength 12000GS

N45 Super Strong Block Ndfeb Neodymium Magnet

N45 Super Strong Block Ndfeb Neodymium Magnet

Xiamen Kingsmagnet has been in magnet industry for 10 more years. We could provide the highest quality and custom size rectangular magnet for you.

High Quality Block Neodymium Magnet

High Quality Block Neodymium Magnet

1.Size: Customized 2.Grade: N35~N55 (M,H,SH,UH,EH,AH) 3.Coating: Zn,NiCuNi,Epoxy,Gold and etc. 4.Magnetized: Thickness,Width,Length or Multipoles 5.Max Operating Temperature: 60~220 degree celsius

Alnico Magnets Alnico5 Magnet Pickup Guitar

Alnico Magnets Alnico5 Magnet Pickup Guitar

Xiamen Kinsmagnet Company have been in magnet industry for 10 more years. Our team could provide you cylinder rod Alnico5 magnetic products.

D5*5mm Neodymium Disc Magnet Round Magnet Neodymium

D5*5mm Neodymium Disc Magnet Round Magnet Neodymium

Xiamen Kingsmagnet has been in magnet industry for 10 more years. We could provide the highest quality round magnet neodymium for the earphone.

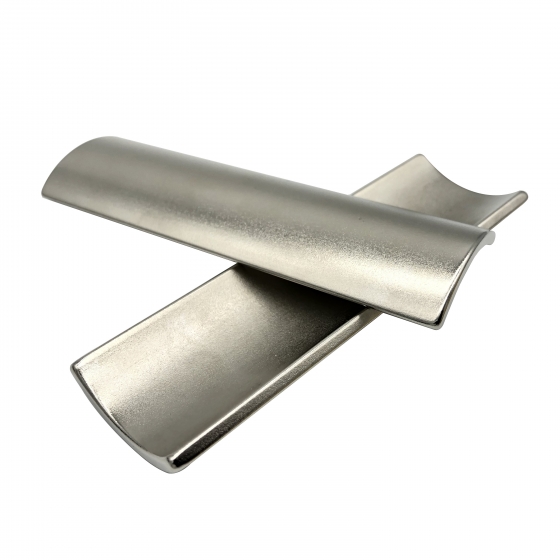

High Performance Arc Neodymium Magnet

High Performance Arc Neodymium Magnet

1.Size: Customized 2.Grade: N35~N55 (M,H,SH,UH,EH,AH) 3.Coating: Zn,NiCuNi,Epoxy,Gold 4.Magnetized: Diametrical direction 5.Max Operating Temperature: 60~220 degree celsius

Trapezoidal Neodymium Magnet

Trapezoidal Neodymium Magnet

1.Size: Customized 2.Grade: N35~N55 (M,H,SH,UH,EH,AH) 3.Coating: Zn,NiCuNi,Epoxy,Gold and etc. 4.Magnetized: Thickness 5.Max Operating Temperature: 60~220 degree celsius

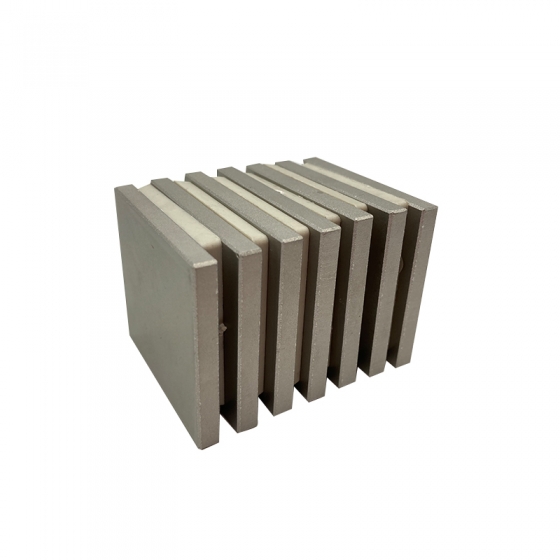

Block Samarium Cobalt Magnet

Block Samarium Cobalt Magnet

1.Dimensions: According to your requirements 2.Grade: YXG26 28 30,YXG26H 28H 30H and etc. 3.Max Operating Temperature: 250 ~350 degree celsius 4.Material:SmCo5,Sm2Co17 5.Magnetized: Axial,Diametrial and etc

Double Countersunk Black Epoxy Block Neodymium Magnets N52 Neodymium Magnets

Double Countersunk Black Epoxy Block Neodymium Magnets N52 Neodymium Magnets

Xiamen Kingsmagnet has been in magnet industry for 10 more years. We could provide the high quality double countersunk black epoxy block neodymium magnets for you.

The professional team to service !